At “VOLBURG group”, we provide high-quality electronic manufacturing solutions that meet our customers’ needs. By leveraging advanced technologies, industry best practices and our expertise, we ensure efficiency, precision, and reliability in every project. We built new business collaborations between EMS`s and OEMs, establishing manufacturing partnerships. We keep our fingers on the pulse of electronic industry and manufacturing sector up-to-date tendencies.

“VOLBURG group” offers highest technological level of certified human and machine capabilities, coordinating worldwide available production resources of our partners. Our global partners database contains various subcontracting services. We add exceptional value to the full production process and guarantee a transparent pricing model for all production stages by taking full responsibility for the entire project’s successful implementation.

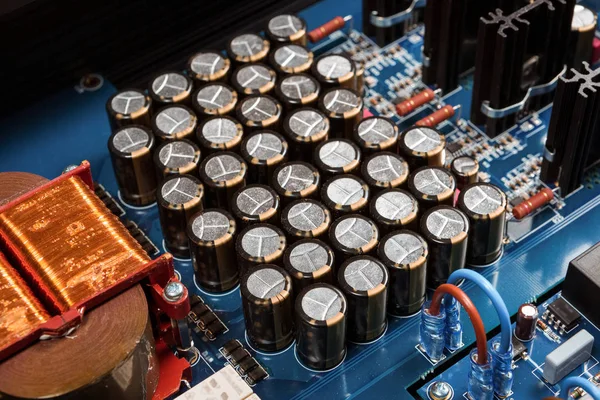

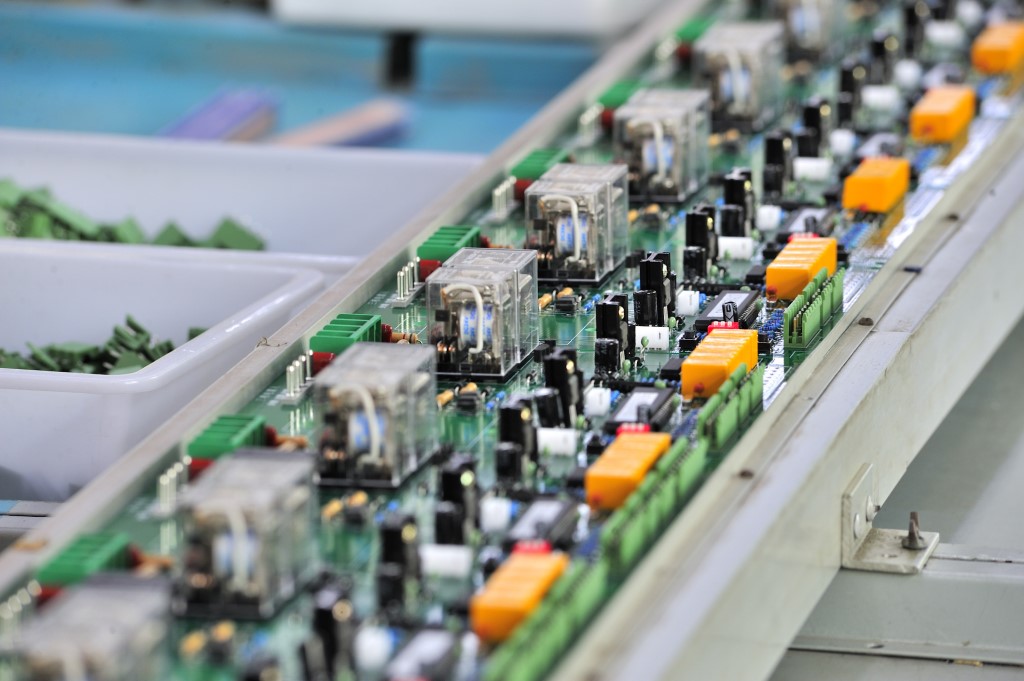

Surface-mount technology (SMT);

Through-hole technology (THT);

Mixed Technology Assembly;

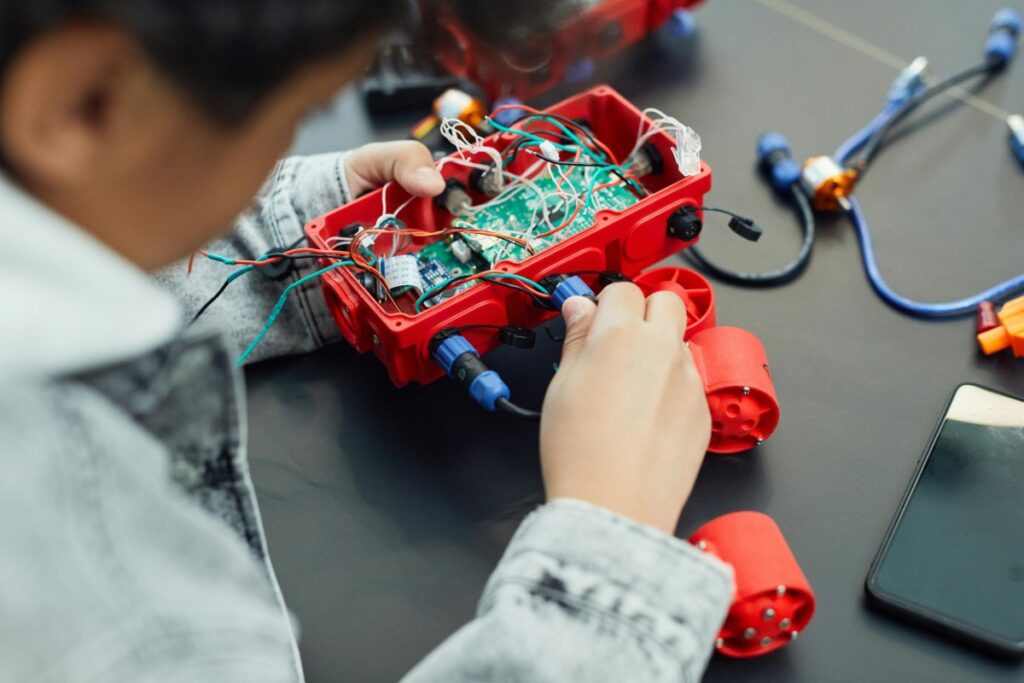

Microelectronics Assembly;

Box-built Assembly;

Electromechanical Integration.

SMT soldering;

Wave soldering;

Selective soldering;

Manual soldering.

Cable Harnessing and Wiring.

Drilling, milling, cutting, welding plastics.

Conformal coating, potting, and sealing to protect against moisture, dust, and harsh environments;

Cleaning and coating process for PCBAs;

Potting & Curing;

Clean rooms.

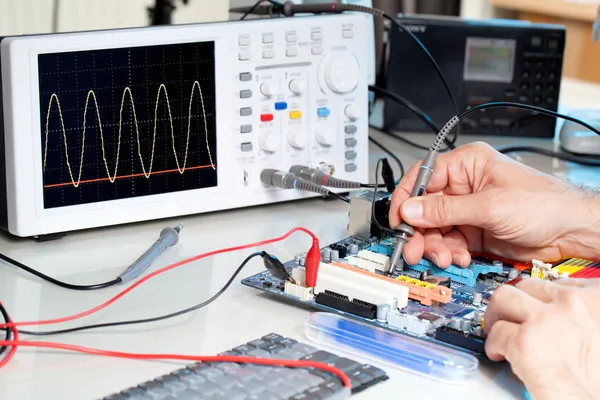

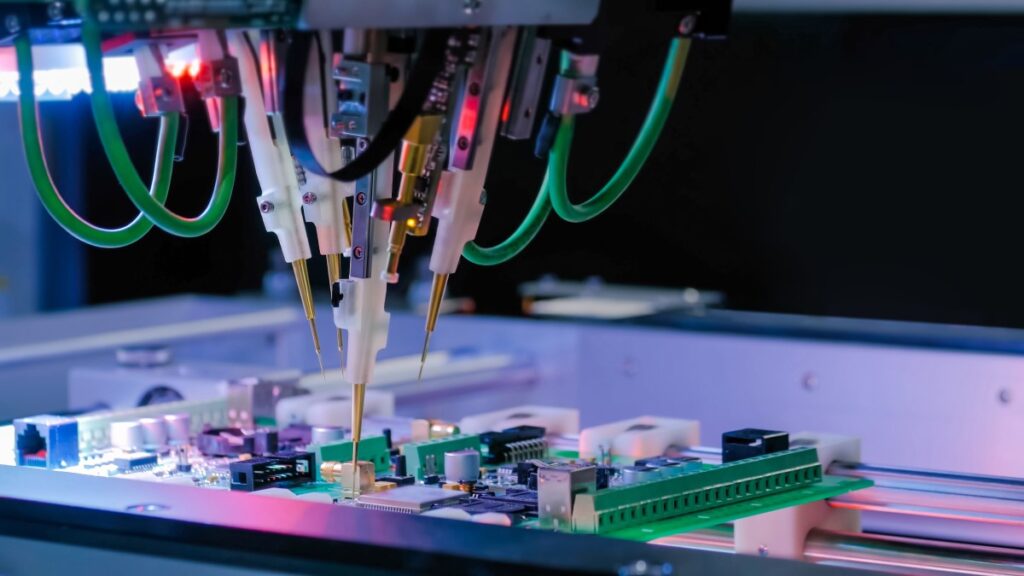

Automated Optical Inspection (AOI);

3D X-ray;

Flying probe;

In-circuit testing (ICT);

Functional testing (FCT);

Bed-of-nails testing;

Hi-Pot, together with FCT;

Burn-In, vibration and environmental testing.

System integration, display/touch screen fitting, membrane keypad mounting, component rack assembly, complete assembly of electronic, mechanical components, and enclosures.

Electromechanical Integration, including Mounting of PCBAs, switches, displays, connectors, and other electronic components inside enclosures, custom cutouts, gasketed seals, and EMI/RFI shielding features;

Automated Press-Fit.

Design and Prototyping. Visualization of test enclosure concepts using 3D printing and CAD services tailored to customer requirements;

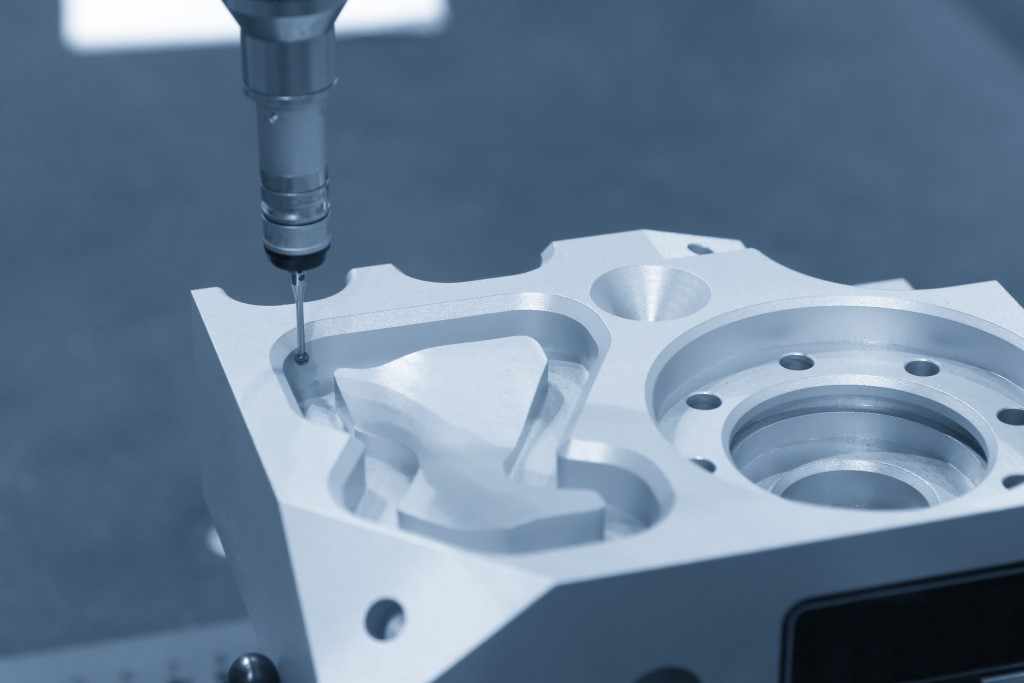

Injection Molding & Plastic Fabrication. Precision injection molding for high-volume production, CNC machining, thermoforming, and casting for low-volume or specialized parts. Surface finishing options: printing, laser engraving, silk-screening, coating, and painting;

Sheet Metal Fabrication. Laser cutting, bending, stamping, and welding of sheet metal components. Surface treatments include powder coating, anodizing, plating, and finishing. Custom mechanical design for durability and aesthetics.

Surface Treatments. Texturing, polishing, laser marking, branding, and decorative finishes, silk-screening, and powder-coating.

“VOLBURG group” expertise is to coordinate worldwide available production resources, which maximally covers customer needs in production technical and technological requirement, quality, flexibility, timelines, pricing policy, logistics. We use production sites worldwide prioritizing and meeting customer needs in subcontracting.

We can find for you and offer the productions matching your batch sizes, annual volumes, PCBA or enclosures complexity, requirements in rolling or one batch deliveries, in-house expertise, engineering and R&D support.

Our database includes a vast international partner network to deliver reliable, high-quality electronic products.